SERVICES

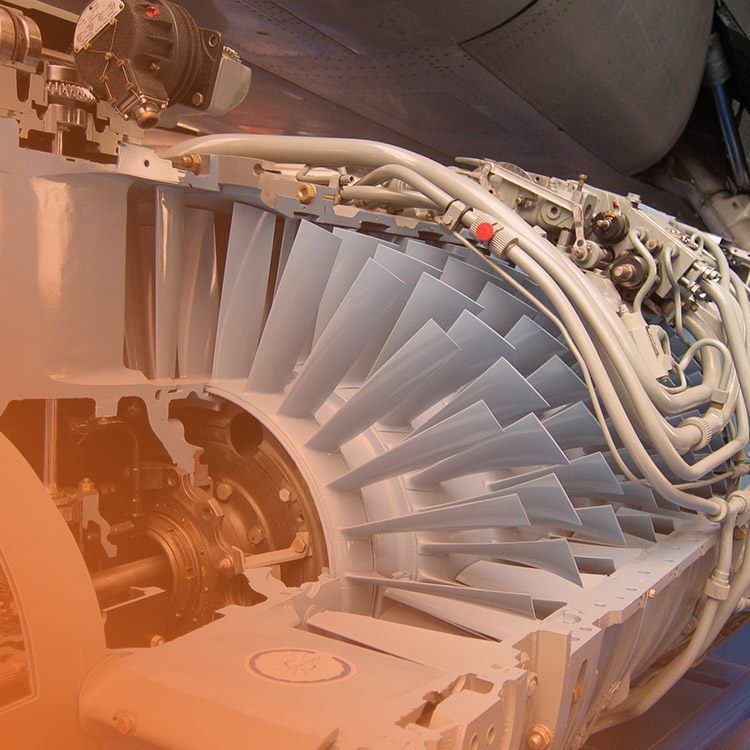

Technical service of rotating equipment

Installation and Commissioning: Our experienced technicians will ensure the proper installation and commissioning of your rotating equipment, including:

Turbines

Generators

Condensers

Reducers

Pumps

Reciprocating and centrifugal compressors

Auxiliary equipment

Routine Maintenance: We offer scheduled maintenance programs to keep your rotating equipment operating at peak performance. Our team conducts thorough inspections, lubrication, alignment checks, and other preventive measures for all types of equipment to minimize downtime and extend equipment lifespan.

Troubleshooting and Repair: In the event of unexpected failures or performance issues, our skilled technicians are available to diagnose and repair your rotating equipment promptly. We utilize advanced diagnostic tools and techniques to identify root causes and implement effective solutions.

Upgrades and Retrofits: As technology evolves, we can help you upgrade your existing rotating equipment to enhance performance, efficiency, and safety.

Technical service of static equipment

Our Services Include:

Mechanical Seal Repair: Our experienced technicians specialize in the repair and maintenance of mechanical seals to ensure proper functioning and prevent leaks in your equipment.

Seal Failure Analysis with Report: In the event of seal failure, our team conducts thorough analysis to identify root causes and provides detailed reports outlining findings and recommendations for preventing future failures.

Application Engineering Consultation: We offer expert consultation services to assist with the selection, design, and optimization of static equipment for specific applications, ensuring compatibility and efficiency.

Access to Proprietary Reliability Software: Gain access to our proprietary reliability software, providing advanced tools for monitoring equipment performance, predicting failures, and optimizing maintenance strategies.

Engineering Support Services: Our team of engineers provides ongoing support and expertise to address technical challenges, troubleshoot issues, and optimize the performance of your static equipment.

System Upgrade Consultation: We offer consultation services for system upgrades, helping you identify opportunities to enhance efficiency, reliability, and safety through equipment modernization and integration of new technologies.

Technical service of dry gas mechanical seals

We deliver comprehensive maintenance solutions to businesses, guaranteeing the efficient, safe, and peak performance of their machinery. Our maintenance services cover a diverse range of static equipment, such as:

Cooling systems

Heating units

Control mechanisms

Pressurized containers

Heat transfer systems

Storage and filtration apparatus

Material segregation devices

Residue elimination systems

Steam generators

With our tailored maintenance strategies, we ensure that your equipment remains in top condition, maximizing productivity and longevity while minimizing risks and disruptions.

Calibration of measuring equipment

We specialize in the precise calibration of various measuring equipment across a spectrum of critical parameters, including:

Dimensional measurements

Pressure assessments

Temperature gauges

Humidity levels

Force quantification

Mass evaluations

Electrical parameters

Time intervals

Frequency analysis

Flow rates

Light intensity

Our calibration services encompass:

Thorough identification, labeling, and documentation of test equipment

Calibration in strict adherence to relevant standards, ensuring accuracy and reliability.

Expert assistance in identifying necessary adjustments, repairs, or replacements as required

Comprehensive management of records, including control reports, equipment summaries, and calibration schedules, for meticulous archival and ongoing equipment tracking.